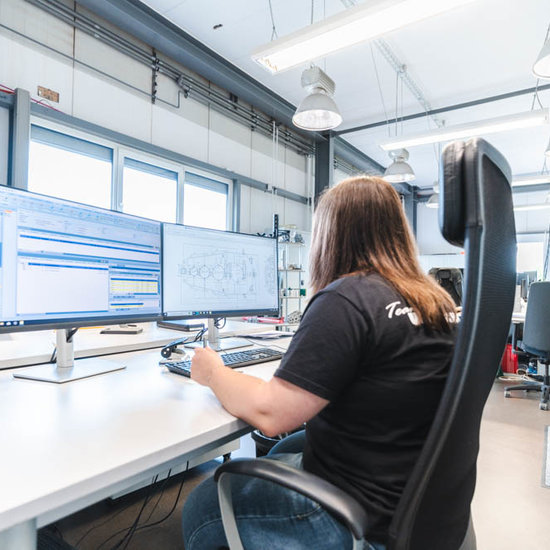

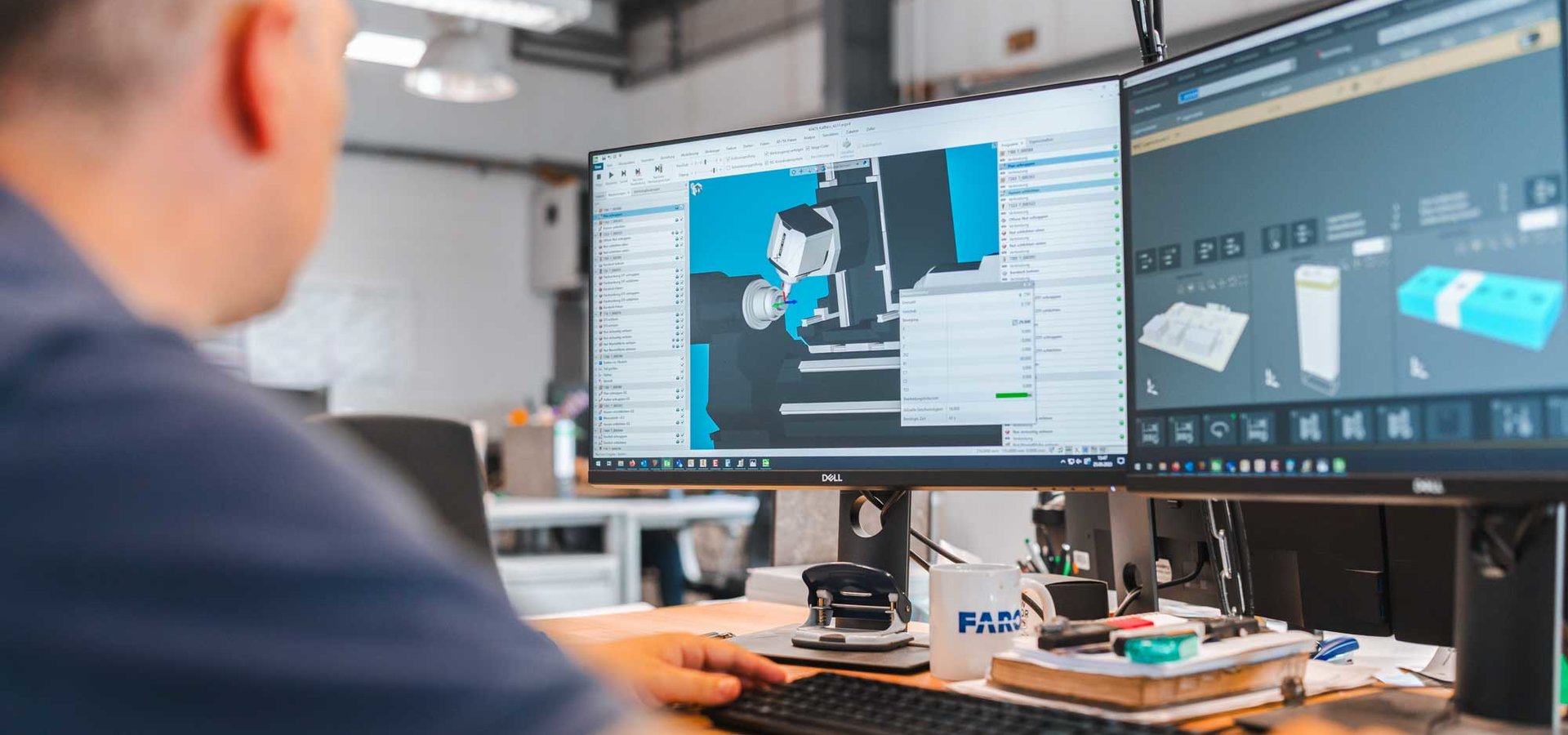

Our development department ensures the professional realisation of your ideas. Your plans are created step by step at our modern workstations using CAD design software. A professionally trained team translates your wishes into a three-dimensional model and then documents them. Another exclusive service for you is our stock of materials, which is always sufficiently filled with common types of sheet metal. This enables us to respond quickly and flexibly to your enquiries and requirements. Both sheet metal and numerous tube and profile dimensions.

Consultancy right from the start. We accompany you from the enquiry to the delivery of the finished part to ensure that your individual requirements and wishes are perfectly implemented.

We offer the measurement of original parts, both at the customer's and at our premises - for dimensionally accurate production at Unterschütz.

Our fully digitalised production process enables rapid internal and external information transfer and thus guarantees rapid production of your parts.