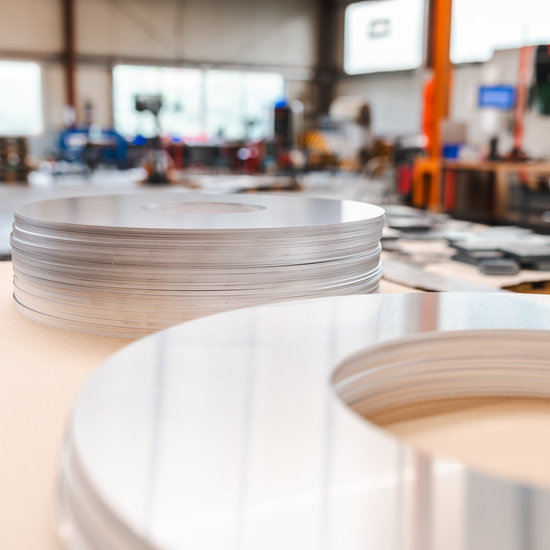

Our development department ensures the professional realisation of your ideas. Your plans are created step by step at our modern workstations using CAD design software. Our professionally trained team translates your wishes into a three-dimensional model and then documents them. Another exclusive service for you is our stock of materials, which is always sufficiently filled with common types of sheet metal. This enables us to respond quickly and flexibly to your enquiries and requirements. Both sheet metal and numerous tube and profile dimensions.

We will be happy to support you with your future plans!

Solution finding, where we work closely with the customer to identify the optimal solutions for their specific needs.

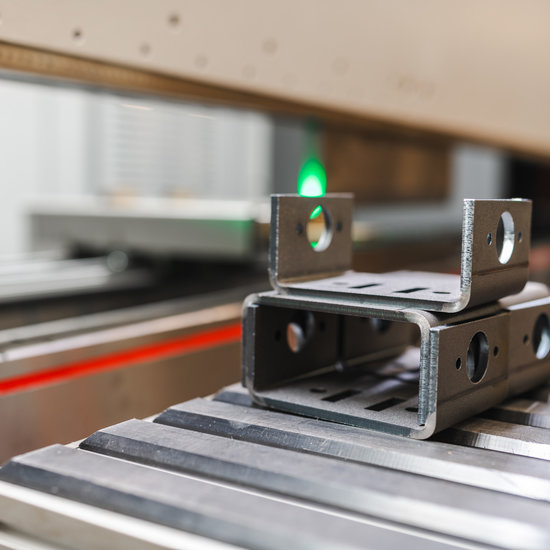

Drafting, using the latest technology and expertise to develop precise and detailed plans for each part.

During the work preparation phase, all the necessary steps are carefully planned and prepared to ensure efficient and high-quality production.

This holistic approach to consulting ensures that every project is professionally managed from start to finish and leads to success.