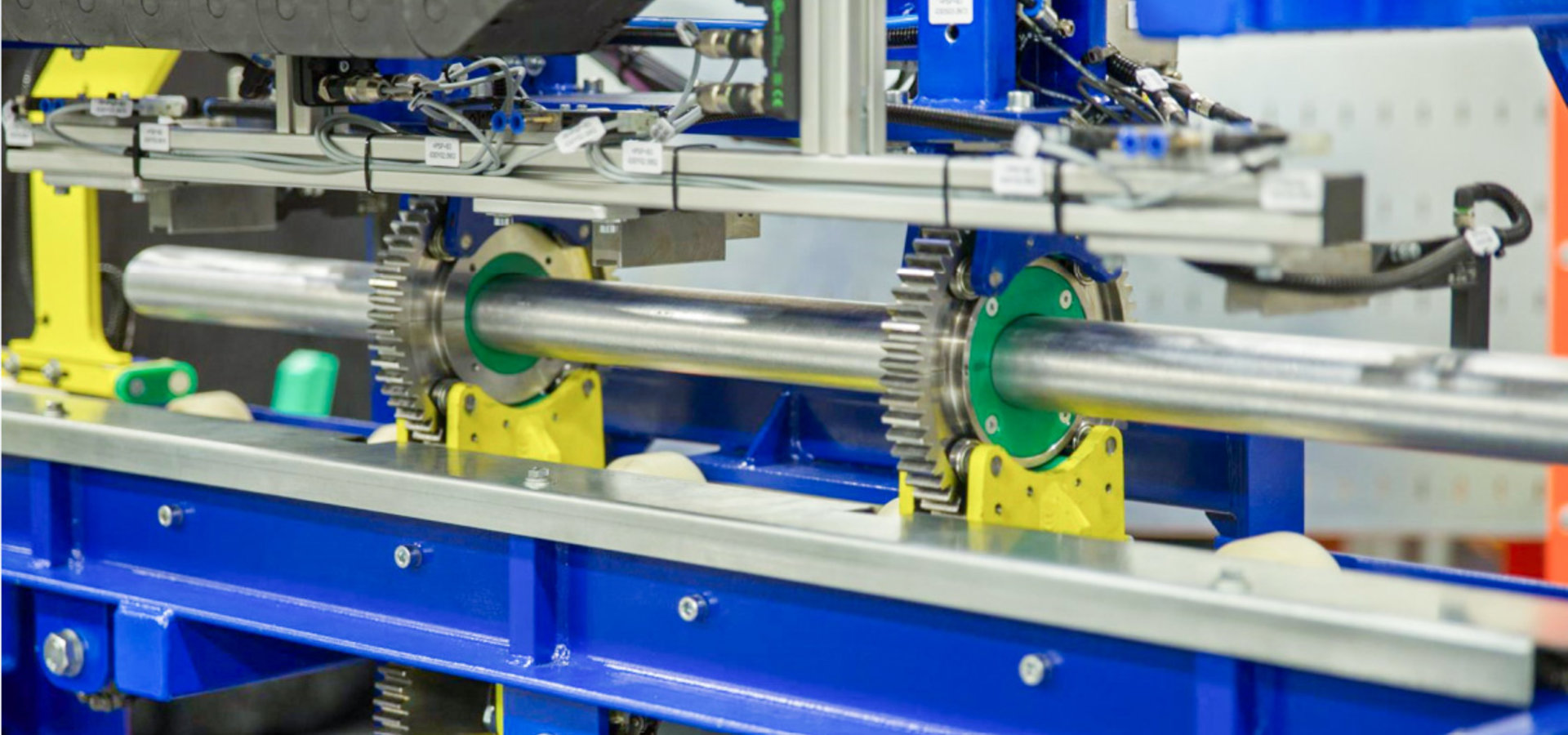

With its casting lines for aluminium rods, Unterschütz meets the most diverse industry requirements. Whether transport, construction, electronics or packaging, we offer our customers customised solutions for every challenge. Our systems are also characterised by their flexibility, which allows us to inspect, store, peel, saw and pack bars in different lengths according to our customers' individual requirements. Benefit from the numerous advantages of aluminium as a material, including its lightweight construction, corrosion resistance and recyclability.